Description

PET bottle chip recycling and cleaning equipment

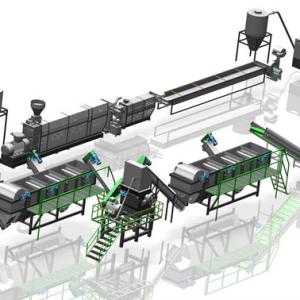

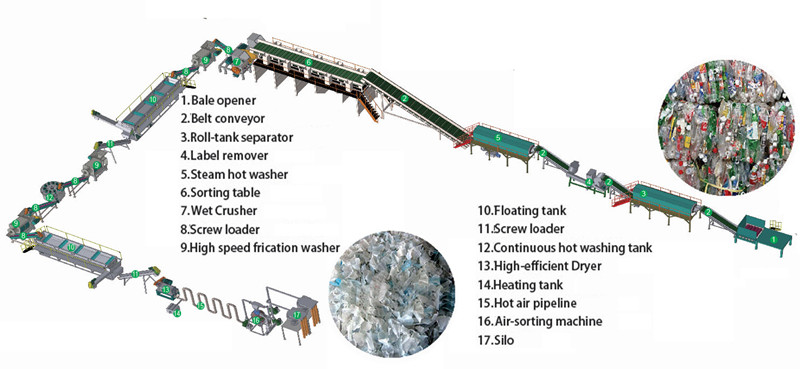

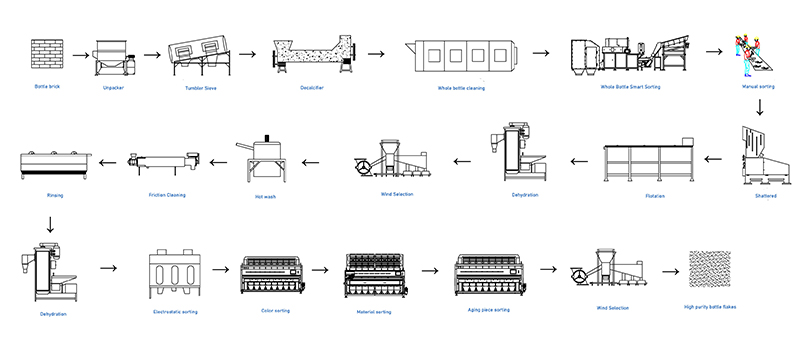

According to different production capacities and cleaning requirements, we have several PET bottle crushing, washing and recycling production lines with different standards. The capacity of this PET bottle crushing, washing and recycling production line is 300 - 2000 kg/h.

The basic equipment of the production line includes: unpacking machine, crusher, rinsing tank, cooking tank, dehydrator, film separation machine and various feeding and conveying machines.

Customers can choose the most suitable PET bottle crushing, washing and recycling production line to produce high-quality PET plastic, which can be used for sales, drawing, production of PET pellets or blow molding.

1. When the waste PET bottle processing machine is processing PET bottles, the final product's humidity is below 1%, impurities are 100 ppm, PVC label content is 100 ppm, and the line capacity ranges from 300 kg/h to 2000 kg/h.

2. The parts in contact with PET materials are made of SUS304, with a thickness greater than 3mm, ensuring the final product has good quality. The waste PET bottle crushing and washing recycling machine line is maintained for long-term use.

3. World-renowned brand components will be applied to the waste PET bottle crushing and washing recycling machine line, such as SKF bearings, Siemens contactors, Omron temperature controllers, Siemens inverters, and Siemens PLC controllers, etc.

4. The entire production line has CE certification..

Bale breaker

The plastic bottle brick unpacking machine, also known as the unpacking machine, is mainly used to dismantle the packaged bottle bricks that have been compressed from recycled waste plastic bottles due to transportation needs. It is also an important equipment used in the primary step of the PET crushing and cleaning process, aiming to quickly break down the ton packages of bottle bricks for the initial impurity removal process. At the same time, it is also convenient for selecting out the dangerous impurities, making it easier for the next crushing process to crush them smoothly. The packaged bottle bricks are directly sent into the unpacking room by forklifts for unpacking. The unpacking speed is controlled by a frequency converter and can be adjusted at will.

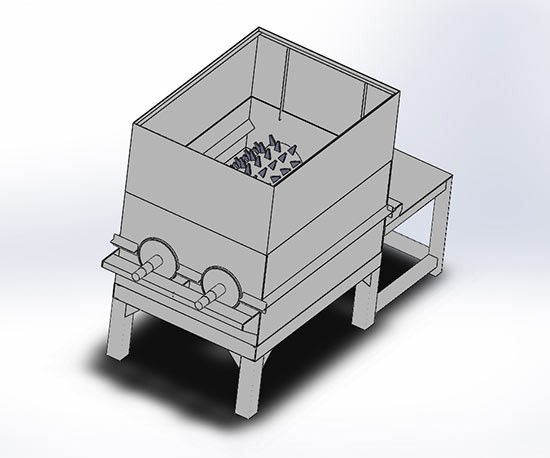

Crushing machine

This machine is specially designed for plastic bottles, cans and other flexible container materials. It is a high-efficiency crusher that is professionally tailored based on the conventional crusher. An additional forced feeding device - a forced downward feeding device - has been added to the conventional crusher. When crushing materials with high elasticity, the output of this machine is more than twice that of the same model conventional machine. Moreover, it is particularly suitable for use in conveyor belt automated feeding production lines. No manual feeding or pressing is required, and it has the function of cleaning while crushing.

PET washing tank

The plastic floatation tank is one of the ideal equipment in the plastic cleaning process. It is suitable for further separation and rinsing of impurities after polyester cleaning, making the bottle flakes cleaner and whiter. It is also a necessary equipment for separating bottle caps from bottle flakes.

Hot washing pot

The high-temperature pot is an essential product in the high-temperature cleaning stage of the plastic recycling process. Under the combined cleaning effect of high temperature and cleaning agent, it can effectively remove stubborn stains such as oil and non-woven adhesives on the surface of the materials, and the cleaning effect is quite obvious.

Water extractor

This machine is an automatic dehydration machine, used for dehydrating various crushed fragments. It is mainly designed for the automatic drying of polyester high orange color materials. Its unique feature is that the output of the automatic drying process does not require manual collection. Besides PET, it can also dehydrate ABS, PP, and PE crushed materials.

Vibrating screen