Description

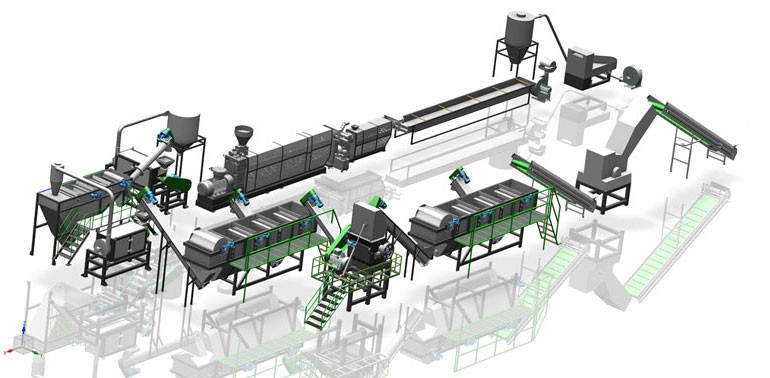

ABS PS household appliance shell fragments are cleaned and recycled for various TV shells, computer shells, refrigerator shells, washing machine shells, air conditioner shells, car battery shells, electric vehicle battery shells, and other large hollow household appliance shells. The shells are dismantled and broken, then subjected to salt water flotation, dehydration and drying, sorting, and the impurities and metals in the materials are separated to produce high-purity engineering raw materials. The production line is mainly used for processing and recycling for reuse. Firstly, the recycled hollow ABS PS household appliance shells are dismantled and broken, processed into small fragments. Then, through high-speed friction scrubbing to remove surface stains, followed by salt water washing to remove some impurities, and then water washing, after centrifugal drying, dehydration and hot air drying, through bouncing sorting machines and electrostatic sorting machines, the metals, rubber and impurities are separated to obtain high-purity various engineering raw materials. They can be made into granules for recycling.

Technical features

The crushing system adopts wear-resistant design to ensure the system operates stably and continuously for a long time.

The high-speed centrifugal cleaning system applies the most suitable rotational speed to apply corresponding blade hitting force to different materials, resulting in good cleaning effect.

The dry electrostatic sorting machine mainly utilizes the principle of high-voltage electric field separation to separate different material materials with different charge levels in the same unit voltage electric field, without generating exhaust gas, wastewater or solid waste, and without any pollution or environmental pressure.

The specially designed air flow wind selection system can effectively separate light substances such as sponge and dust in the household appliance dismantling and sorting process, improving the purity and recovery rate of various materials.

The strong magnetic drum magnetic separation system efficiently separates the steel in the materials and controls the purity of the steel materials. Due to its special working mode, it is not easy to adsorb impurities when separating steel.

The entire line is automatically controlled, with interrelated operation between each unit, and the automation degree is high.

The use of circulating water ensures the cleaning effect while reducing water consumption.

Through theoretical calculation and multiple measurements, the mechanical operation details of the crushing, cleaning and drying sections are adjusted to avoid material loss due to excessive processing.

The production line can be equipped with a sewage and wastewater treatment system, which can filter and recycle the sewage, meeting the environmental protection discharge standards, and solving your worries.

ABS Household Appliance Shell Crusher

This machine is mainly used for crushing the electronic shells of used refrigerators, washing machines, air conditioners, computers, televisions, etc. It has low energy consumption, is easy to operate, and the tool change is simple and quick. The tool holder is optimally designed, resulting in high output. The hourly output can reach approximately 1500 to 3000 kilograms.

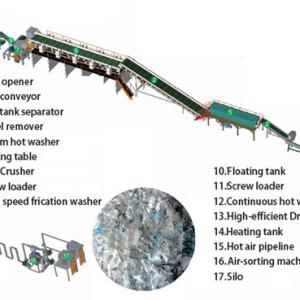

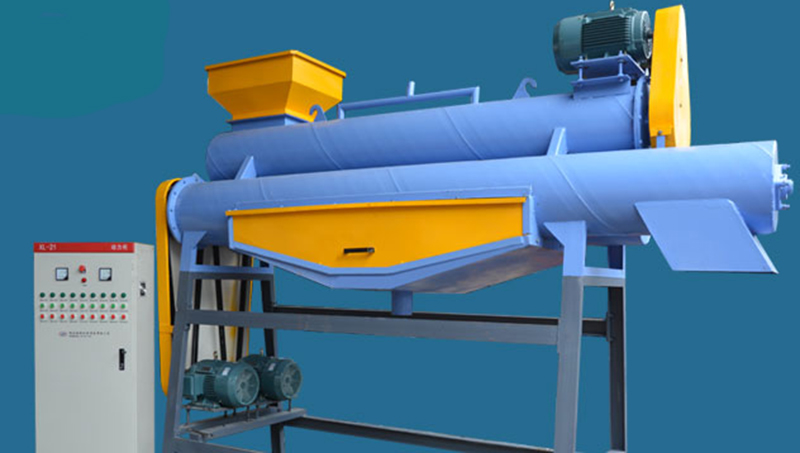

Friction washing machine

The efficient three-tank cyclic friction cleaning machine can remove oil stains, self-adhesive materials, and other strongly adhered impurities from plastics such as PP, PE, and ABS. Moreover, this equipment has a small footprint, requires less water, and is the preferred choice for those with high requirements for plastic cleaning results. The principle of the three-tank cleaning machine is to allow the raw materials to be thoroughly scrubbed in the machinery. The materials are first subjected to friction cleaning in the first tank, then enter the second tank for further friction cleaning, and finally enter the third tank for friction cleaning before being discharged.

Washing tank

This set of floatation separation water tank is applicable for most plastic floatation separation processes, mainly including the separation of bottle caps and bottle bodies from PET bottle chips, and the cleaning of PE Wahaha chips, etc.

Hot washing pot

The high-temperature pot is an essential product in the high-temperature cleaning stage of the plastic recycling process. Under the combined cleaning effect of high temperature and cleaning agent, it can effectively remove stubborn stains such as oil and non-woven adhesives on the surface of the materials, and the cleaning effect is quite obvious.

Water extractor

This machine is an automatic dehydration machine, used for dehydrating various crushed fragments. It is mainly designed for the automatic drying of polyester high orange color materials. Its unique feature is that the output of the automatic drying process does not require manual collection. Besides PET, it can also dehydrate ABS, PP, and PE crushed materials.

Vibrating screen