Description

The HDPE & PP cleaning and recycling line is used to process various types of HDPE and PP waste plastics. After processing, it can be used to produce plastic particles and manufacture plastic products.

HDPE plastic is mainly used for the production of various packaging materials, such as bottles and barrels, which are well-known. Generally, large-sized HDPE materials need to be shredded first, while small-sized ones can be directly crushed.

The different application places of HDPE materials determine different impurity residues. We can design and adjust corresponding schemes according to different impurity residues.

The HDPE cleaning and recycling line is basically applicable to the recycling processing of PP materials of similar sizes.

Suitable for cleaning various plastic products with high resilience and a thickness of approximately 1-25 millimeters.

Using circulating water, it ensures the cleaning effect while controlling the water flow and evaporation volume.

The crushing system adopts a wear-resistant design to ensure the system can operate continuously for a long time.

Through theoretical calculations and multiple measurements, the mechanical operation details of the crushing, cleaning, and drying processes were adjusted to avoid material loss due to excessive processing.

The entire line is automatically controlled, with the various units operating in a correlated manner. It has a predictive function for possible abnormal situations to ensure the safety of the system.

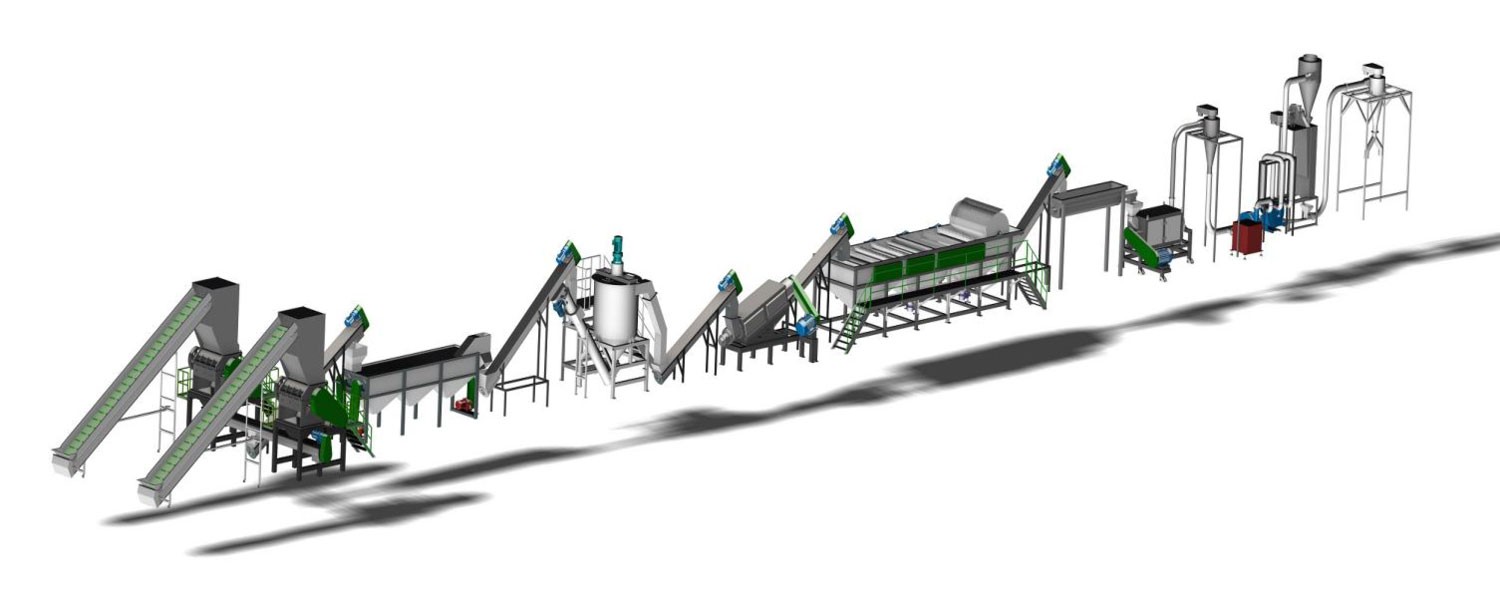

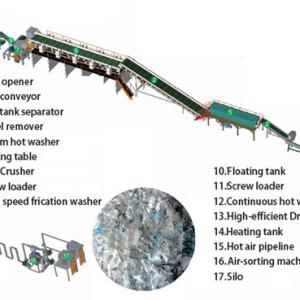

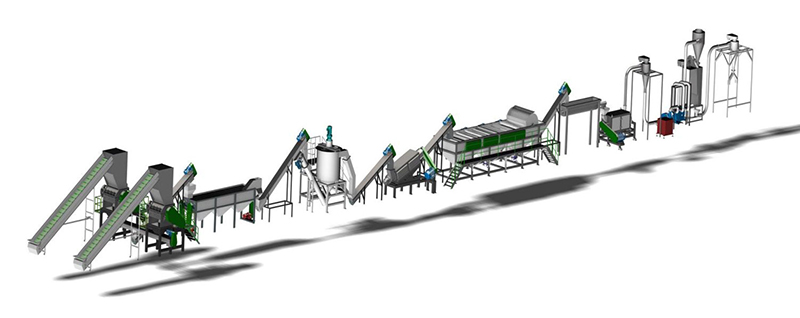

HDPE & PP Cleaning, Processing and Sorting Line

Unpacking machine + belt conveyor + grinder + low-speed friction + rinsing machine + dehydration machine + cleaning machine + elevator + label separator + hot air drying system + sorting equipment

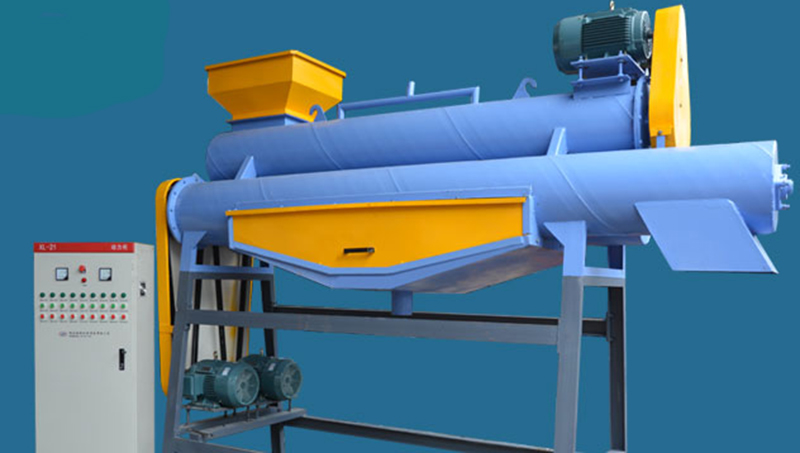

Crushing machine

This machine is specially designed for plastic bottles, cans and other flexible container materials. It is a high-efficiency crusher that is professionally tailored based on the conventional crusher. An additional forced feeding device - a forced downward feeding device - has been added to the conventional crusher. When crushing materials with high elasticity, the output of this machine is more than twice that of the same model conventional machine. Moreover, it is particularly suitable for use in conveyor belt automated feeding production lines. No manual feeding or pressing is required, and it has the function of cleaning while crushing.

Friction washing machine

The efficient three-tank cyclic friction cleaning machine can remove oil stains, self-adhesive materials, and other strongly adhered impurities from plastics such as PP, PE, and ABS. Moreover, this equipment has a small footprint, requires less water, and is the preferred choice for those with high requirements for plastic cleaning results. The principle of the three-tank cleaning machine is to allow the raw materials to be thoroughly scrubbed in the machinery. The materials are first subjected to friction cleaning in the first tank, then enter the second tank for further friction cleaning, and finally enter the third tank for friction cleaning before being discharged.

Washing tank

This set of floatation separation water tank is applicable for most plastic floatation separation processes, mainly including the separation of bottle caps and bottle bodies from PET bottle chips, and the cleaning of PE Wahaha chips, etc.

Hot washing pot

The high-temperature pot is an essential product in the high-temperature cleaning stage of the plastic recycling process. Under the combined cleaning effect of high temperature and cleaning agent, it can effectively remove stubborn stains such as oil and non-woven adhesives on the surface of the materials, and the cleaning effect is quite obvious.

Water extractor

This machine is an automatic dehydration machine, used for dehydrating various crushed fragments. It is mainly designed for the automatic drying of polyester high orange color materials. Its unique feature is that the output of the automatic drying process does not require manual collection. Besides PET, it can also dehydrate ABS, PP, and PE crushed materials.

Vibrating screen